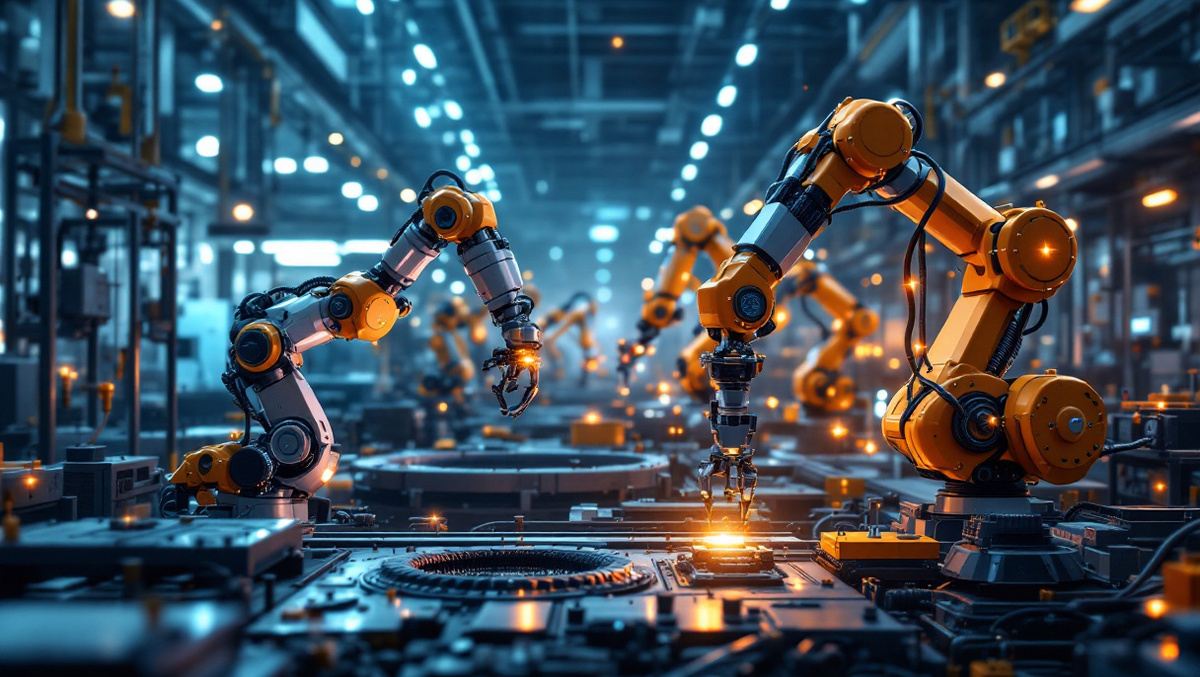

A new generation of AI-powered robots is set to revolutionize the manufacturing industry. Companies are deploying intelligent machines capable of performing complex tasks, learning from real-time data, and adapting to changing production demands. This advancement significantly enhances efficiency, reduces errors, and lowers operational costs.

These robots use advanced sensors, computer vision, and machine learning algorithms to interact safely with human workers, creating collaborative environments that combine precision automation with human decision-making.

Enhancing Production Efficiency

Manufacturing plants integrating AI robotics report faster production cycles and improved quality control. Automated systems can detect defects, adjust machinery settings in real time, and predict maintenance needs, minimizing downtime.

The ability to analyze large datasets allows manufacturers to optimize supply chains, reduce waste, and forecast demand more accurately, giving companies a competitive advantage in a fast-paced global market.

Applications Across Industries

AI-powered robotics are being adopted in automotive assembly, electronics production, pharmaceuticals, and food processing. In the automotive sector, robots handle intricate assembly tasks with high precision, while pharmaceutical companies use AI for packaging, sorting, and quality assurance.

Electronics manufacturers leverage robots to assemble delicate components, reducing error rates and ensuring product consistency. Food processing facilities benefit from AI for sorting, packaging, and hygiene compliance, enhancing efficiency and safety.

Workforce Implications

While automation enhances productivity, it also raises concerns about workforce displacement. Companies are focusing on reskilling employees to operate and maintain AI systems, emphasizing human oversight in decision-making processes.

Collaboration between humans and robots, known as “cobotics,” ensures that employees work alongside intelligent machines rather than being replaced, fostering safer and more productive workplaces.

Future Trends and Innovation

Experts predict that AI-powered robotics will become increasingly autonomous, capable of complex problem-solving and predictive maintenance. Integration with Internet of Things (IoT) devices will enable real-time monitoring and adaptive responses to operational challenges.

Startups and tech giants are investing heavily in AI robotics R&D, aiming to develop smart factories that minimize waste, energy consumption, and human error while maximizing productivity.

FAQs

What are AI-powered robots?

AI-powered robots use artificial intelligence, sensors, and machine learning to perform tasks autonomously or collaboratively with humans in industrial settings.

Which industries benefit most from AI robotics?

Automotive, electronics, pharmaceuticals, food processing, and logistics industries are seeing major gains.

Do AI robots replace human workers?

Not entirely. Cobotics allows humans to work alongside AI robots, and companies focus on reskilling employees for new roles.

What are the main advantages of AI robotics?

Improved efficiency, precision, reduced downtime, enhanced quality control, and predictive maintenance are key benefits.

How will AI robotics evolve in the future?

Robots will become more autonomous, integrated with IoT, capable of complex problem-solving, and increasingly adaptive to dynamic production needs.

Conclusion

AI-powered robotics are transforming manufacturing by merging automation with intelligence, precision, and adaptability. The technology enables faster production, higher quality, and better resource utilization, driving competitive advantages across industries.

While challenges related to workforce adaptation remain, the rise of cobotics ensures humans and robots can collaborate effectively. As AI robotics continue to advance, the manufacturing sector is poised for unprecedented innovation, efficiency, and productivity in the coming years.